Make your drilling more efficient

The machines in the rugged FORWARD UN6 (Pilot Hydraulic Control) utilize well-proven technology. It can perform above or below ground in a wide range of core drilling applications. The FORWARD UN6 rig are adaptable and can be tailored to fit the unique needs of your operation.

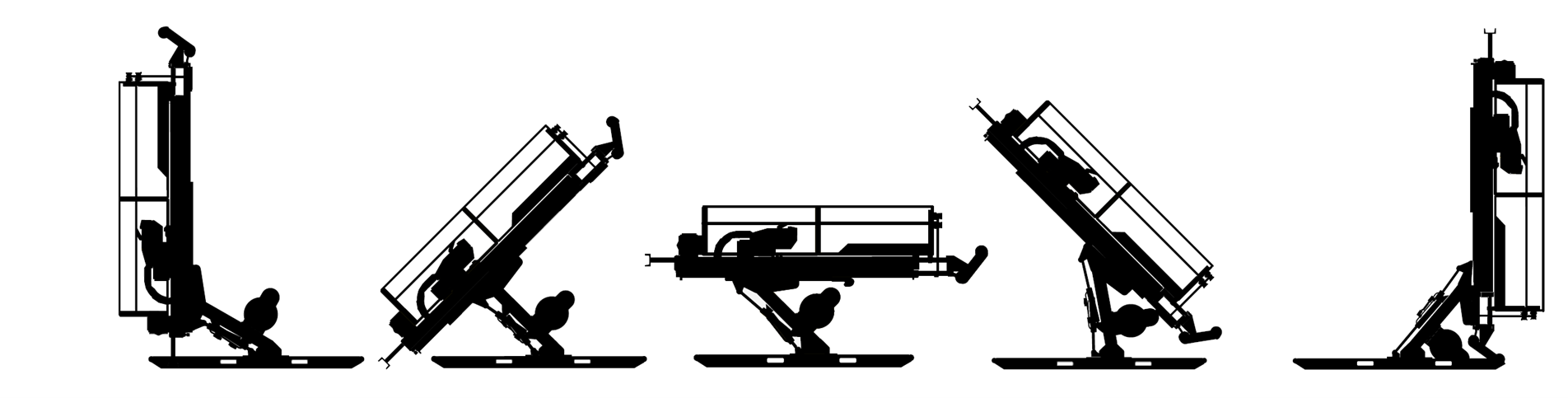

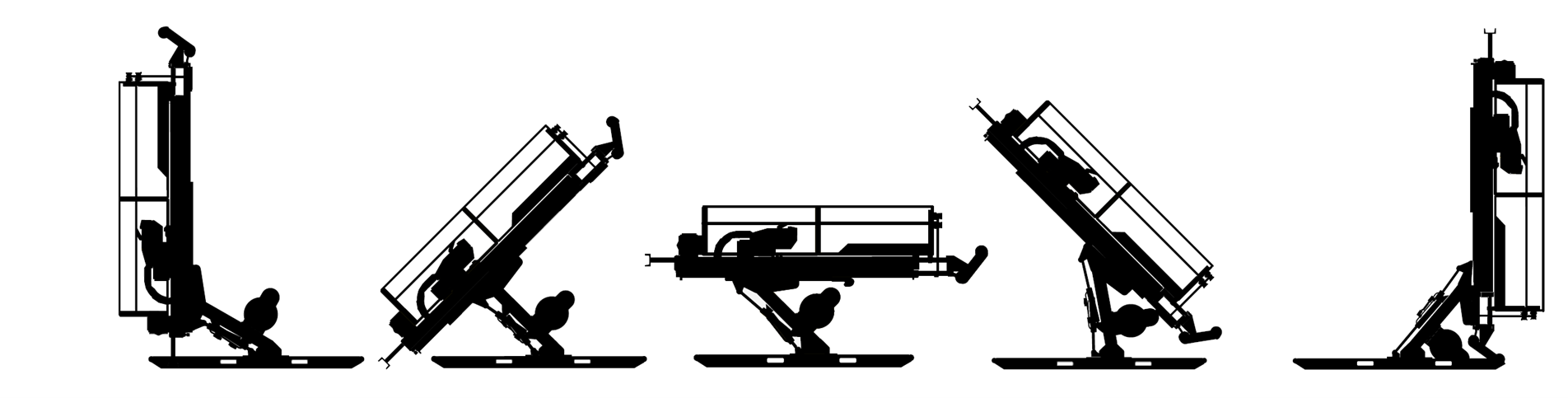

FORWARD UN6 core rig are equipped with a skid-mounted chassis as standard for easy transport. A compact design enables the rigs to manoeuvre within cramped quarters causing minimal disturbance to surrounding operations. FORWARD machines are ideal for both underground exploration and surface applications. A modular design means that rigs can be configered with various interchangeable feed lengths and rotation units. Future reconfiguration is easily carried out with minimal fuss.

The unique combined turntable and positioning arm fitted to the FORWARD UN6 core rig enables easy, fast and accurate set up.

The industry-standard in exploration

The industry-standard in exploration

Powerful and compact, the FORWARD UN6 features a versatile modular design. It can be fitted with various alternatives and options to best suit your particular requirements regarding rock type, hole diameter and hole depth. FORWARD machines drill straight upwards, downwards or horizontally, enabling you to get the job done easily.

Main benefits

Compact yet flexible,

Main benefits

Compact yet flexible, featuring a modular design that can be tailored to fit your specific needs.

Built for productivity, FORWARD UN6 rig is safe and easy to operate so you get the best outcome.

Trusted for reliability, a FORWARD UN6 rig can be relied on to retrieve superior core samples, time-after-time

Drilling time is maximized

Drilling time is maximized by the electrical power units and cleverly designed hose arrangements which feature a hose ladder to reduce wear.

The pilot hydraulic control system provides the operator with full control. The operator station works at a reduced hydraulic pressure (max 80 bar) which means it’s safer for the operator and lighter in weight.

Feed frame with equal pull and push force

Feed frame with equal pull and push force

The feed frame is the backbone of the drill rig. This robust system uses a direct feed cylinder coupled to a chainless feed. The system reduces maintenance costs and provides a pull and push force which is equal. FORWARD UN6 rig has increased capacity for up-hole drilling without the need for modifying anything on the feed. The feed frame is also fitted with wear strips which increase service life and reduce repair costs.

Rod holder closes using gas pressure

Rod holder closes using gas pressure

The gas spring rod holder opens with hydraulic pressure and closes with gas pressure. The gas cartridge lasts for up to a million cycles providing a low total cost of ownership. To enhance safety, the rod holder and chuck are synchronized to eliminate human errors and remove the risk of dropping rods. Jaws with TC inserts are available to increase the holding force when drilling medium to deep holes.

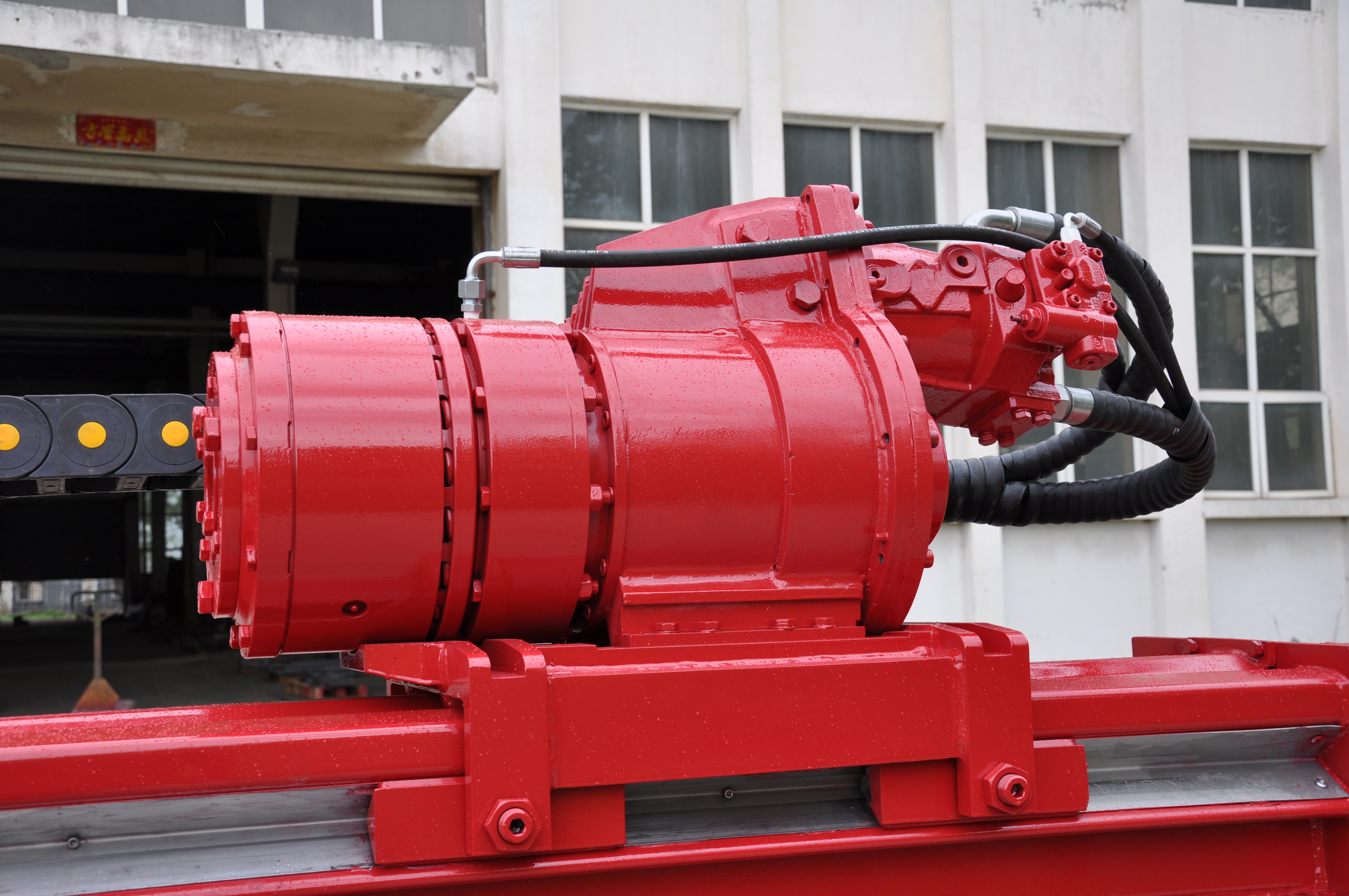

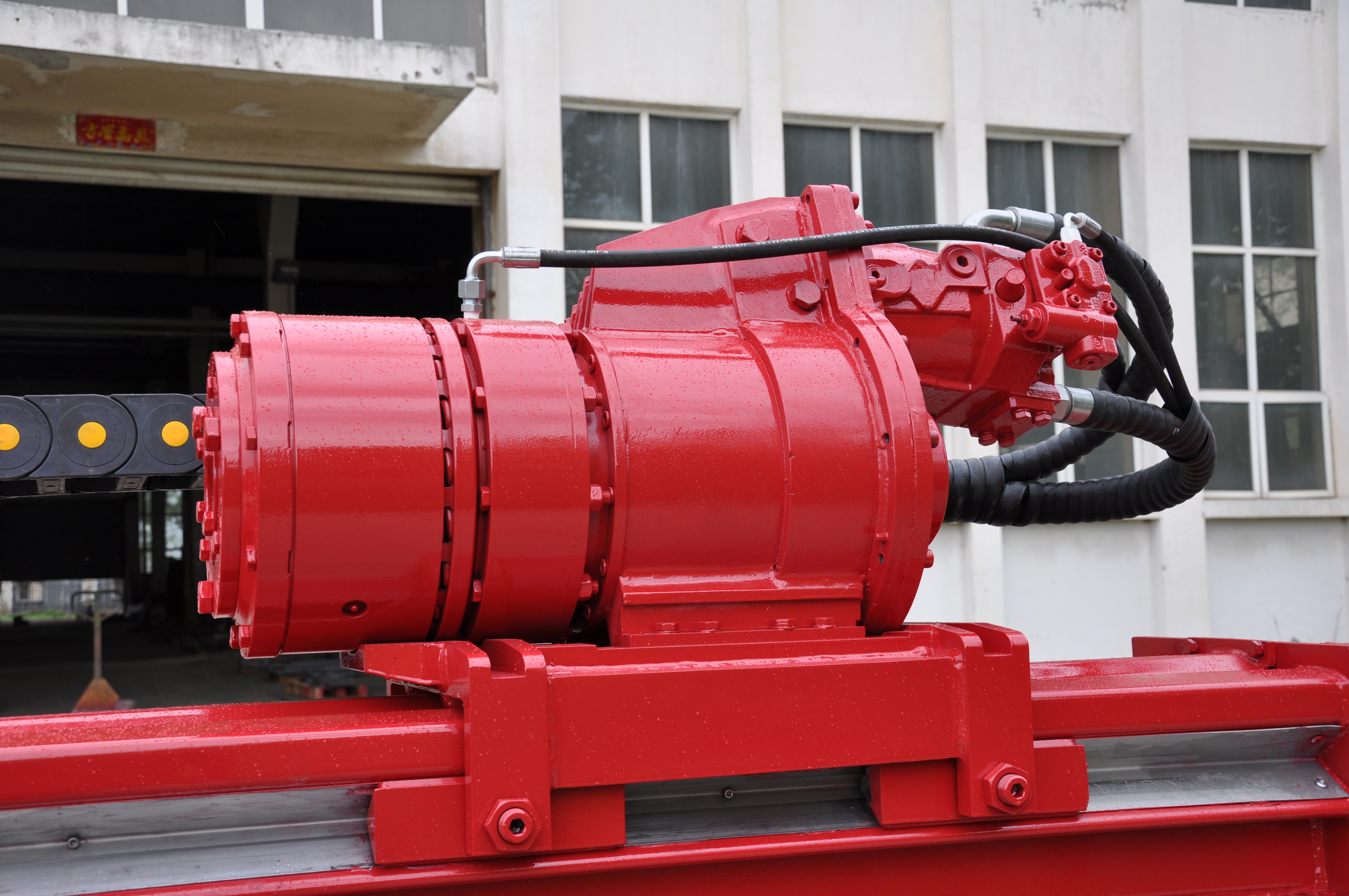

A rotation unit of your choice

A rotation unit of your choice

The rotation unit constitutes the muscles of the rig, and certain applications require more strength. Depending on rock conditions and your desired hole dimensions, there is a rotation unit to suit the job. Each unit is designed with oversized bearings to increase durability. The gear case is sealed completely to handle drilling from +90° to -90° angles. A patented hydraulic chuck with quick-change jaws provides both superior rod grip and quick, easy rod changes.

FORWARD UN6

FORWARD UN6

The FORWARD UN6 is a powerful and flexible machine. It’s available with various feed lengths, standard and deep hole feed cylinders and three different rotation heads. The rig can be configured to serve a large variety of drilling applications.

The FORWARD UN6 is fitted with a synchronized rod holder and chuck.

This greatly reduces the risk of dropping rods due to human error.